At 12inx12inx15.5in, you can print models that 90% of other printers could not. EXTRA LARGE: Printer CR10 V3 comes with one of the largest build spaces available.Make sure this fits by entering your model number.It will certain improve, and I’m interested to see what happens next. Nevertheless, this release is the very first from Autodesk for this functionality. They also tend to include far more specific machine and material information that would have to be manually input into Fusion 360. The alternatives, although standalone, are far more sophisticated and easy to use. But for casual users accustomed to other slicers, Fusion 360’s slicing system is a bit strange.Īt this early stage I cannot see serious users making use of Fusion 360’s slicing systems.

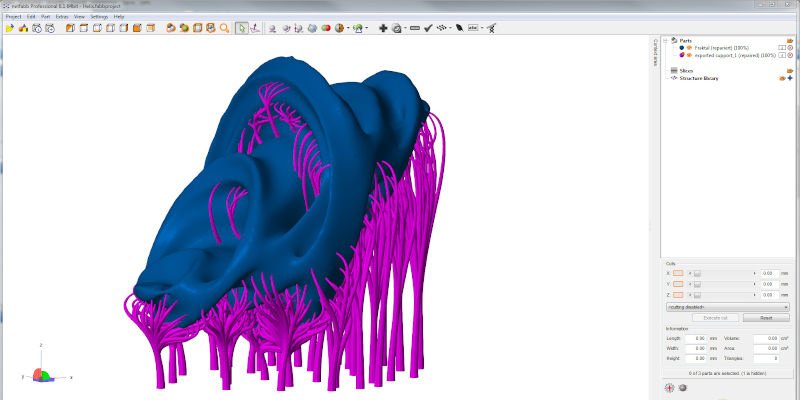

Compared to other slicing systems, the flow through Fusion 360’s slicing system seems awkward and less than optimal.Įventually, however, those who “live” in Fusion 360 may find this beneficial as the visual interface paradigms remain consistent throughout the work. They’re easy to use, but a bit different and new users often find them confusing. One interesting observation is that the Fusion 360 slicing system must adhere to the unusual visual interface protocols used by the entire Fusion 360 system. Again, this is perhaps due to the fact that Autodesk could have to support arbitrary devices in the future.īut users of Ultimaker Cura or other modern slicing systems, the Fusion 360 options will likely appear to be something that is several years old in terms of sophistication. However, when you dig in deep it really does appear that the options presented are at a basic level only.

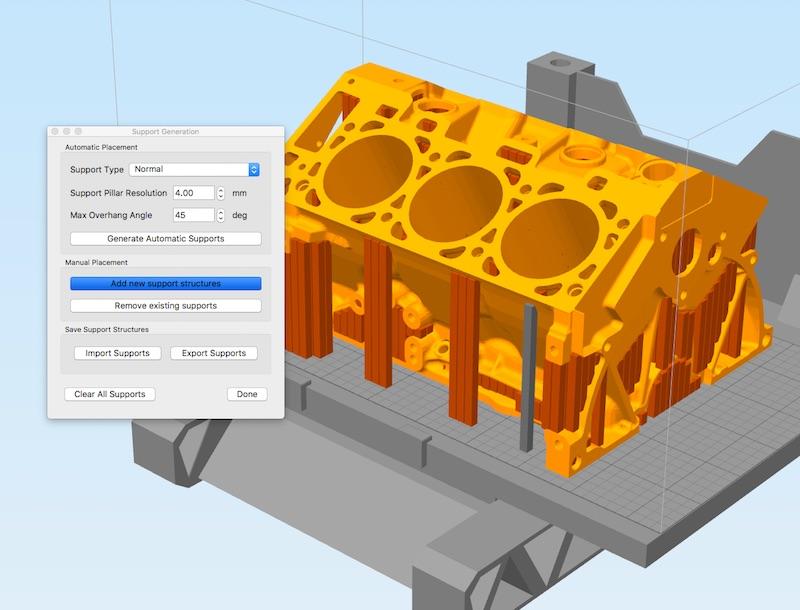

I’m not sure how they are going to handle this as the system evolves in the future.įusion 360 includes pre-made profiles for only 12 materials, and not only is it likely the material you want is not on the list, you will have to tweak the profile to match the particular machine you’re using.įor the print job settings, Fusion 360 provides a set of parameters as seen here. Meanwhile, Fusion 360 would ultimately have to provide profiles for ALL machines. To be fair, Autodesk is at a significant disadvantage here because a 3D printer manufacturer like, say, Ultimaker, needs only to provide profiles for their equipment. There is a shortage of defined material profiles. This does not yet seem to be the case with Fusion 360’s slicing system. The more popular 3D print slicing systems today, such as Ultimaker Cura, PrusaSlicer/Slic3r, or Simplif圓D are actually quite sophisticated, having evolved over multiple years to arrive at their current powerful states.

XYZprinting, for example, is perhaps the 3D printer manufacturer with the highest number of different 3D printer models, yet they have only one entry on the list, the Da Vinci Color Mini.įortunately, Autodesk has included a number of the most popular machines, including:įor those with other machines, there is still a possibility: Autodesk offers a “Generic FFF Machine”, whose configuration can presumably be tweaked to match an unsupported device. In fact, there are only twentyish 3D printers listed. Note that only selected machines are available in Fusion 360, and there are many models unavailable. As such, Autodesk has smartly included the ability to generate GCODE for select machines from the following 3D printer vendors:

Of course, 3D print slicing depends significantly on the specific machine involved, because they can have additional or slightly different GCODE commands. A look at the updated “Manufacture” space shows that CAM can be done for milling, turning, cutting and, now, additive. Now it appears that Autodesk has decided to include 3D print job preparation in their CAM workflow. New “Additive” option appears in Fusion 360 Manufacturing space

0 kommentar(er)

0 kommentar(er)